|

Dalian Hoyi Bearings Co., Ltd.

|

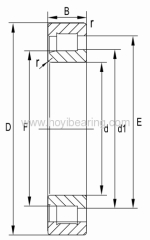

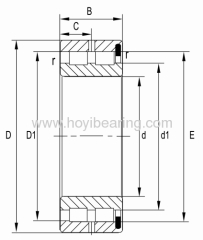

Cylindrical Roller Bearing Four Row

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

These bearings are an excellent choice for applications where there are particularly heavy radial loads combined with high speeds.

Cylindrical roller bearings with four or more rows of rollers are used almost exclusively in rolling mills. They have lower friction than other roller bearings and can be successfully used where high speed operation is called for. The low cross-sectional height of cylindrical roller bearings means that the roll necks can have a large diameter in relation to the roll itself. In four-row cylindrical roller bearings, the rollers are guided between integral or non-integral flanges on the outer ring. The inner ring is without flanges; axial displacement of the shaft in respect to the housing can therefore be accommodated by the bearing within certain limits. Depending on the application, four-row cylindrical roller bearings can be supplied with a cylindrical bore or a tapered bore. The inner and outer rings may be in one piece or in more than one piece. Cylindrical roller bearings with more than four rows of rollers and cages are used primarily in small cold rolling mills for flat products, where the rolling forces are considerable and rolling speeds high. Multi-row bearings are produced for roll neck diameters of up to approximately 220mm. The outer ring has two non-integral flanges and the rollers are guided between these. The inner ring is without flanges. Limited axial displacement of the shaft with respect to the housing can therefore be accommodated by the bearing. Dimensions The dimensions of the bearings with series designations listed in the tables conform to ISO 15-1981. Misalignment Multi-row cylindrical roller bearings are not designed to accommodate any misalignment. Tolerances With some exceptions the four row cylindrical roller bearings with cylindrical or tapered bore have a dimensional accuracy corresponding to tolerance class P6 and a running accuracy to tolerance class P5. Six row cylindrical roller bearings are manufactured to tolerance class as Normal specifications. Radial internal clearance Four row cylindrical roller bearings with cylindrical and with tapered bore, are produced with C3 or C4 radial internal clearance, while six row cylindrical roller bearings are manufactured with radial internal clearance depending on the application. On customer's request bearings with different radial internal clearances are available. All cylindrical roller bearings that present helical groove on the inner ring bore are made with C2 radial internal clearance. Cages In relation to the execution four row cylindrical roller bearings are fitted with either two double-pronged machined roller guided cages in brass or steel, pin-type cages of steel (with pierced roller) or machined cages of brass with vent-hole. Some executions are supplied with steel pressed sheet. Heat treatment With some exceptions multi-row cylindrical roller bearings undergo to special stabilising treatment S0 which makes them suitable for operating temperatures up to +150° C. On customer's request it's possible to have other stabilising treatment as: S1 (use to +200°C) S2 (use to +250°C) |

Multi-Row Cylindrical Roller Bearing

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Four Row Cylindrical Roller Bearings

Single Row Cylindrical Roller Bearings

Double-Row Cylindrical Roller Bearings

Double Row Roller Bearing

Row Taper Roller Bearing

Cylindrical Roller Bearing

More>>

.jpg)

.jpg)

.jpg)

.jpg)