|

Dalian Hoyi Bearings Co., Ltd.

|

inch taper roller bearing

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

.Fruitful bearing selling history

.OEM Supply

.Small order accepted

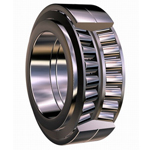

Tapered roller bearings consist of four interdependent components: the cone(inner ring), the cup(outer ring), the tapered rollers(rolling elements) and cage (roller retainer) Tapered roller bearings are uniquely designed to manage both thrust and radial loads on rotating shaft. The steeper the cup angle, the greater the ability to bearing to handle thrust loads |

Metric Size: Hoyi is able to make double-row tapered roller bearing from bore diameter 120mm to 800mm

Our advantage

Our advantage

1) High quality. 100% Inspection to make sure that every piece would be high quality products!

2) Very Large Stock. Much Shorter Delivery Time!

3) Manufacture bearings and packing according to your requirements!

Our leading products

Taper roller ball bearing, Deep groove ball bearing, Spherical roller bearing, Cylindrical roller bearing

Tapered roller bearings are generally used to support combined load mainly consisting of radial load.Their cups are separable for easy assembling.During mounting and using,radial clearance and axial clearance can be adjusted and pre-loaded mounting can be made.

It mainly suitable for machine tool spindle , Large and medium-sized reducer.

1.The bearing should be stored in the clean and dry places at a relative humidity less than 65%.

2.Reclean and recoat the bearing with oil at an interval of a year in the storage.

3.When mounting the bearing, clean up the oil seal and coat the clean high quality lubricating oil.

4.Apply force evenly to the bearing and be sure never to use a hammer directly in mounting case. To mount with an tight interference fit on a shaft, heat the bearing to about 90 C to 100 C in the mineral oil

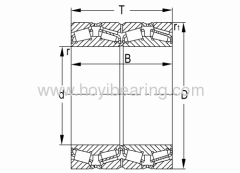

Double-row taper roller bearing

Double-row taper roller bearing

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Inch Taper Roller Bearings

Taper Roller Bearing

Row Taper Roller Bearing

Single Taper Roller Bearing

Metric Taper Roller Bearing

Inch Roller Bearing

More>>

.jpg)